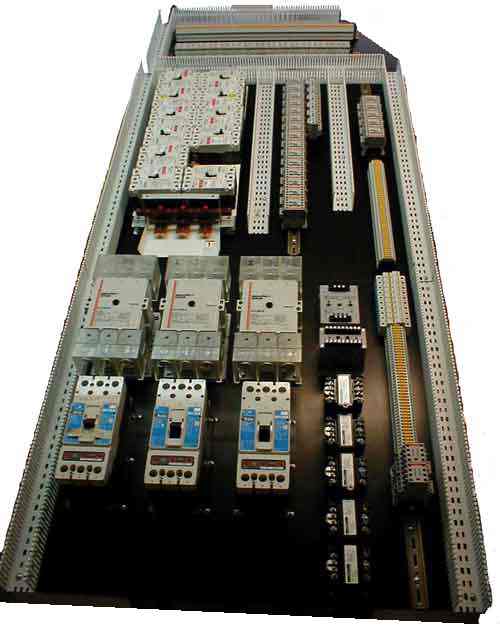

The example at left illustrates the modular electrical locker package that we developed for certain railway passenger car electrical locker situations. In cases where our NW-25100 or other standard Northwest Rail Electric packages will not provide everything that is needed for the control system in the electrical locker, a considerable amount of customization can be gained by taking standard modules and combining them to produce a custom control system. This avoids having to construct a completely custom system for the passenger car, as well as replacement of a single small panel in the event of damage rather than working on a single large panel.

From Top To Bottom:

The module at the very top of this unit provides overall system and power control. Part of this includes selecting the source of power from any of several possible sources, including HEP, one of the two under-car diesel generator sets, or a yard power connector.

This passenger car is equipped with two generators under the floor, so the dual generator control and automation systems are visible on the next four panels: a generator control panel and a complete set of power monitoring equipment including frequency, current, and voltage measurement for each generator. Certain car owners prefer the analog meters shown here, but packages with LED numerical displays are also available. Generator control systems may include the control unit shown here, or either of the more sophisticated engine control units shown on our Generator Contols Page, in the second and third photographs from the top.

A closer look at the generator control panel is located on our Custom Control Units page.

At the very bottom of this unit are two HVAC control units - each controls temperature and humidity at one end of the car. Each unit controls a single stage of dehumidification, two stages of air conditioning, and two stages of heat. In addition, there is an emergency cooling option, which is controlled by the key switch. This bypasses all of the automated controls and sets the air conditioning to run at maximum capacity.

This control unit is actually installed on the door of the electrical locker with a piece of plexiglass over the top. This allows the crew on the car to read the measurements without opening anything. It also prevents any tampering with the control systems.

Behind this unit are several other panels that can only be accessed by opening the door on which these panels sit. These other panels include the 480 volt circuit breaker panel, contactors for the power selection system, which includes two separate HEP trainlines and two generators as possible power sources (four total systems for the power selection system to deal with). There is also a large 120 / 240 volt circuit breaker panel, a 12 volt DC panel that connects to the various battery systems, and several smaller panels. To access all of these other items, the door on which the visible part of the control system is mouted is simply swung open.

Note that many of the circuit breakers have been labeled with engraved tags. Where appropriate space has been left for additional future tags. All of the circuit breakers will be visible through the glass fronted enclosure when the system is installed, so it doesn't even have to be opened to determine if a circuit has been turned on or a breaker tripped. The display screen, processing system, USB port (circular connector to the left of the display screen) and certain other components located on the second panel from the top were required by the customer to be covered while in motion, and thus the secondary cover for those systems. The blank covers over the spare circuit breaker positions have not yet been added in this view. The white adhesive paper visible on the door protects the glass part of the enclosure door until the system is installed. Quite a lot of custom sheet metal was involved in positioning the various types of circuit breakers and the display system at a uniform height.

The unit pictured here is a fairly typical example of the complex locker packages that Northwest Rail Electric custom-designs for the railroad passenger car market. The two big circuit breakers and contactors at the bottom right of the panel on the left are what determines the source of power: HEP or generator power. The small equipment on the far left is part of the HVAC control system, and some of the other components are part of current control (such as phase detection and overcurrent protection) that helps protect the system on the passenger car. Above the large grey contactors is a 480 volt circuit breaker panel for several of the large loads on this passenger car. This includes 480 volt to 120/208 volt transformers, HVAC equipment, and several dining car kitchen loads (such as a large hot water heater and oven) that require 480 volts, 3 phase to operate. The panel on the right includes some switching equipment, with the vast majority of the space taken up with 120/208 volt circuit breaker panels, which provide power to all of the household voltage loads on the various parts of the passenger car.

Right: All Northwest Rail Electric packages contain a terminal block or plug system so that the customer can easily connect the system into the car. We attempt to use a system that best meets the customer needs. This may take the form of ring terminals, compression terminals, or various plug and socket connectors. Some of these are determined by existing equipment that the customer may have that our equipment needs to connect with. Our current favorite connector for many situations is a circular plastic plug and socket connector that is far easier to work with than the military style connectors that are used in similar applications, but has proven to be rugged enough to withstand railroad service.

Right: All Northwest Rail Electric packages contain a terminal block or plug system so that the customer can easily connect the system into the car. We attempt to use a system that best meets the customer needs. This may take the form of ring terminals, compression terminals, or various plug and socket connectors. Some of these are determined by existing equipment that the customer may have that our equipment needs to connect with. Our current favorite connector for many situations is a circular plastic plug and socket connector that is far easier to work with than the military style connectors that are used in similar applications, but has proven to be rugged enough to withstand railroad service.Left: In contrast to the first several control systems pictured on this page, this small, single panel control system was designed for a passenger car with a severe space shortage. NWRE developed this package to have four 480 volt loads (such as heating, air conditioning, 480 volt to 120 volt step down transformer for lighting, and the HEP main breaker), a small number of 120 volt lighting or electrical receptacle loads, and a very simple HVAC control system.

Note:

Along with these custom packages, we also offer a standard complete control package in our NW-25100 unit. Variations of this package satisfy the needs of many passenger cars.

The Custom Packages described on this page are not required to convert most passenger cars to modern electrical service, but may be needed if the customer has very unique electrical requirements.

Custom Electrical Locker Packages have been built that include:

The traditional passenger car electrical locker does not have space on the door for controls, such as the package shown at the top of the page used. It is, however, still possible to fit a complete passenger car control system into an older-style passenger car electrical locker. The photograph above shows a package that includes, starting from top left and working downward, a control panel for a number of low voltage DC loads on the car, an HVAC control unit similar to that of the NW-25100, a generator contorl panel similar to the NW-GC500, and some of the power switchgear at the bottom. On the right side of the package, there is a 120 / 208 volt 3 phase circuit breaker panel for all the 120 volt and 208 volt single phase and 208 volt three phase electrical loads. Below that is a 480 volt panel for such items as the air conditioning compressor, electric heat system, hot water boilers, and dining car ovens. Under that panel is more of the switchgear for the power selection system.

Here is a closer look at the switchgear on the bottom of the unit:

The main piece of this locker package is a variation of the NW-25100 HVAC Control System but with a few unusual features. Among these, the temperature display is in the middle of the control panel cover. The controls include a programmable layover control that operates the heat or air conditioning with a fairly broad dead range, but normal HVAC operation turns the system to function with temperatures comfortable to passengers. There is another control for baseboard heat. The control at the top of the panel gives battery voltage for the car 72 volt battery system, with a selector switch to turn on the marker lights on either the A or B end of the car. The panels below the HVAC control are various custom control circuits that do not need to be accessed under normal circumstances. One variation of this panel has a series of 24 volt circuit breakers for turning on various low voltage loads, including LED over-seat lights.

Once again, you will notice the 480 volt circuit breaker panel in the upper left of the panel, and switchgear and circuit breakers in the lower left for three power sources. What is different about this panel is the piece missing from the upper right corner. In order to be able to fit this package into the confined space of the electrical locker on this passenger car, we found it desirable to use space inside the area where the roof of the car joins the side, and this cut was necessary.

Many of today's passenger cars use nickel cadmium batteries. This package takes 480 volt three phase power from the HEP system and charges a fairly large 120 volt nickel cadmium battery bank. Also included are the 480 volt circuit breakers and meters for monitoring the battery voltage and HEP system voltage feeding the chargers.

The HVAC Control System is at the top of the unit, and is extremely simple. These are the blue boxes at the top.

This package has an extremely simple control panel for heating and power. While it is difficult to see in the photo, the cover of the control unit is hinged to provide easy access to the interior of the control panel and easy replacement, upgrading, or repair of any components insdie.

The five black switches directly below the meters are control voltage circuit breakers, which provide circuit breaker protecton for such items as the low voltage supply to the HVAC control system, relay and contactor coil power, and emergency lighting.

The circuit breaker panel visible below the control unit is for the 220 volt and 120 volt electrical systems on the car.

Here is another control unit installed in an electrical locker on a passenger car. This package also includes power switching controls, control circuit breakers, and HVAC control. There are four HVAC zones on this car, and so there are four control sets. The generator control system includes a loud alarm that alerts the crew if a problem arises with the generator. Meters and power selection equipment at the very top of the panel provide a complete control panel for the crew.