This particular control system was designed to control two generator sets, with one generator acting as the back-up generator for the other. Furthermore, the generator systems were designed to feed both 208 and 480 volts 3 phase power without using transformers, using a rather unusual twelve wire system. For a few more photographs of it, please see our LMTO-01 Generator Package page.

Intended for a railroad with an even more exceptionally harsh operating environment than normal, This PLC based system has a hinged glass cover for observation of some of the indicator lights on the electronic devices.

This cooling control package was designed to survive the harsh railroad environment while still providing all of the required control.

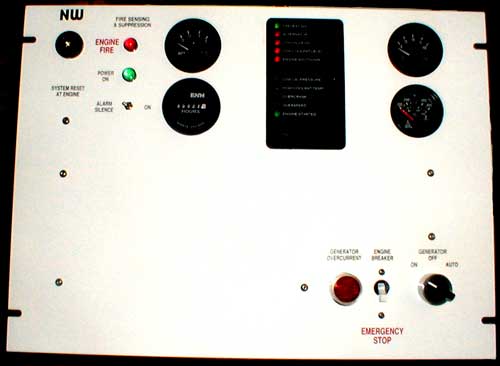

The generator control system pictured here is similar to the one used on the door mounted control system pictured at the top of our Custom Locker Packages page.

It is only part of a system, and it connects to several other panels using circular connector units.

The control unit at left would probably not be used for temperature control on an entire passenger car in most cases. However, it makes an extremely convenient package for certain very simple items, such as water pipe freeze protection, baseboard heat control, circulation fan control, or some other similar item. As it is pictured here, the unit has not yet had the wiring installed.

There was only one odd shaped space available on the passenger car system that is controlled by this unit, and so we developed this "L" shaped enclosure to fit that space. Control signals from temperature detection come from inside the car and all of the required switching circuits that convert those signals into actual power circuits to control the HVAC system are in this unit.

Placing the entire generator control and the switchgear inside an enclosure has been done in a few cases where the unit was to be used on a dedicated power car, and the car owner wanted to have the generator control right next to the engine. In order to protect the generator control unit as best as possible from dust, dirt, and all manner of other items that would cause problems, the system was placed in an enclosure.

Note that the unit pictured here is actually a control panel for a car that actually has two generators. Several dual generator control systems have been built by Northwest Rail Electric, including an automatic paralleling package.

Similar enclosed generator controls have been used in under-car situations where the control system was mounted underneath the car. (Note: in passenger cars, this is normally not recommended, as it is usually most convenient for someone inside the car to access the control unit. In one or two cases, however, our generator control units have been installed on unmanned freight cars, and in that case there would never be anyone inside the car. Thus, the need for a weatherproof under-car unit.)

Note also that the unit pictured here has connectors so that it can be quickly plugged into the generator and switchgear portion of the system.

The above panel is an example of several different types of panels that we have built for control of DC systems. In the above example, the unit has a switch for determining the condition of three sets of batteries for three different systems. There are also circuit breaker switches for the various DC loads on the car.

The above example is a detail view of one of the locker packages pictured on the Custom Locker Packages page. In this second case, the absolute maximum number of DC circuit breakers has been used. Direct current circuits can sometimes be a lot more than a simple set of emergency lights, and these customized DC control panels help certain customers meet special needs on their passenger cars. This is particularly the case on railroad business cars and other situations where there is 74 volt DC locomotive voltage circuits for certain railroad specific equipment.

This more complex DC control system also included emergency light relays and certain elements of the battery charging circuit.